About Iron Balls and Broken Needles

About Iron Balls and Broken Needles

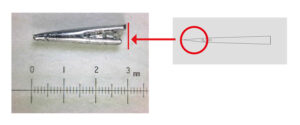

Foreign needle tips are generally broken needles with different sizes, cut surfaces, etc., and their mass is not constant. Therefore, Hashima considers it inappropriate to use needle tip size as a standard for needle detection.

Therefore, Hashima determines machine specifications and performance based on the iron ball equivalent.

The cut surface is not straight and it is difficult to assume mass by length.

Comparison of needlepoint and iron ball mass

The following are the results of mass measurements of needle tips and iron balls at official measuring institutions.

| Iron ball sample name | MASS | NEEDLEPOINT SAMPLE NAME | MASS |

| Fe0.8mm φ | 0.002083g | DB×1 SF No.9 3mm | 0.002060g |

| DB×1 No. 7 3mm | 0.002700g | ||

| DB×1 No. 8 3mm | 0.002940g | ||

| Fe1.0mm φ | 0.004063g | DB×1 No. 9 3mm | 0.004180g |

| DB×1 No. 11 3mm | 0.005160g | ||

| Fe1.2mm φ | 0.007030g | DB×1 No.14 3mm | 0.007040g |

| DB×1 No. 16 3mm | 0.007690g | ||

| Fe1.5mm φ | 0.0137370g |

*Samples were cut at right angles to the needle tip.

As shown in the table, the 3 mm tip of DB×1 SF No. 9 has almost the same mass as the 0.8 mmφ test piece.

Since the test piece and the needle are made of the same components, they are considered to be almost the same in terms of volume.

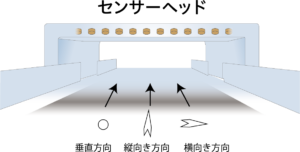

The above is only a comparison of the mass (volume) of the needle tip and the steel ball. The actual folded needle has a longitudinal and a transverse direction to the sensor head, and the detection response differs depending on the direction.

As shown in the figure below, the detection response varies depending on whether the needle tip enters the sensor head vertically, horizontally, or vertically.

Therefore, it is not always possible to detect a foreign object if its mass exceeds that of the test piece.

To address this problem, we also offer a device for twice needle detection and a 2-head type needle detector equipped with two heads at different angles.